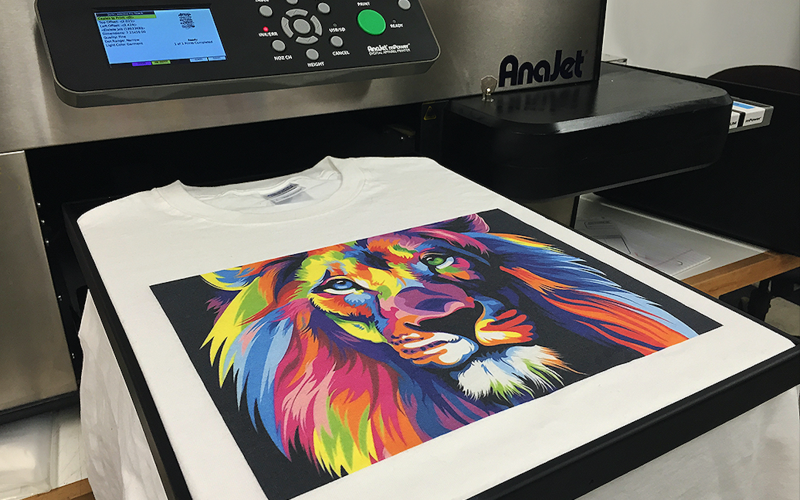

Direct-to-Garment (DTG) printing has emerged as a revolutionary method for customizing t-shirts and other garments with intricate designs, vibrant colors, and high-quality prints. This innovative printing technique offers unparalleled flexibility, allowing for the reproduction of detailed artwork, photographs, and complex graphics with precision and accuracy. In this comprehensive guide, DTG Printing Shop Dallas will delve you into the fascinating world of DTG printing, exploring the process, technology, benefits, and creative possibilities that make it a preferred choice for custom apparel decoration.

Understanding DTG Printing

DTG printing, also known as digital garment printing or inkjet-to-garment printing, is a cutting-edge printing technology that enables designs to be printed directly onto fabric using specialized inkjet printers. Unlike traditional screen printing methods that involve creating separate screens for each color in the design, DTG printing allows for full-color prints to be reproduced directly from digital files with remarkable detail and clarity.

The Process of DTG Printing on T-Shirts

DTG printing involves several key steps, each essential for achieving high-quality prints on t-shirts and other garments. Here’s a detailed overview of the process:

- Pre-Treatment: Before printing, the t-shirt fabric is pre-treated with a special solution to enhance ink absorption and ensure vibrant, long-lasting prints. This pre-treatment process helps to create a smooth and even surface for the ink to adhere to, resulting in crisp and clear prints.

- Design Preparation: Graphic design software is used to digitally prepare the printed design. This can be a logo, artwork, photograph, or any other graphic element. Designs are typically saved in a rasterized format, such as JPEG or PNG, at high resolution to ensure optimal print quality.

- Printing Setup: Once the design is finalized, it is loaded onto the DTG printer’s computer system. The printer is calibrated to ensure accurate color reproduction and print alignment. The t-shirt is then placed onto the printer’s platen, which holds it securely in place during printing.

- Printing Process: The DTG printer applies the ink directly onto the fabric of the t-shirt using a series of tiny nozzles. The printer moves back and forth across the garment, depositing the ink in precise locations according to the digital design file. Multiple passes may be required to achieve full color coverage and saturation.

- Curing: After printing, the ink is cured or dried using heat and pressure to ensure durability and washability. This may involve heat pressing the printed garment or passing it through a conveyor dryer. Curing the ink helps to bond it to the fabric and prevent fading or bleeding over time.

- Finishing Touches: Once the ink is cured, the printed t-shirt is inspected for quality control, ensuring that the print is clean, clear, and free of defects. Any excess ink or residue is removed, and the t-shirt is folded or packaged for distribution.

Advantages of DTG Printing

DTG printing offers several advantages over traditional printing methods, including:

- High-Quality Prints: DTG printing produces vibrant, high-resolution prints with sharp details and smooth gradients, allowing for the reproduction of intricate artwork and photographic images.

- Full Color Capability: DTG printing allows for full-color prints to be reproduced directly from digital files, without the need for separate screens or color separations.

- Versatility: Cotton, polyester, mixes, and even dark-colored clothing may all be printed with direct-to-garment (DTG) printing.

- Quick Turnaround: DTG printing is ideal for on-demand or small-batch production, as there are no setup costs or minimum order quantities required. This allows for quick turnaround times and fast delivery of custom-printed garments.

Creative Possibilities of DTG Printing

DTG printing offers endless creative possibilities for customizing t-shirts and other garments. Some popular applications of DTG printing include:

- Custom Apparel: DTG printing allows individuals to create personalized t-shirts, hoodies, and other garments with unique designs, logos, and artwork.

- Merchandise Printing: DTG printing is commonly used to create custom merchandise for bands, artists, brands, and events, including concert t-shirts, promotional apparel, and souvenir items.

- Fashion Design: DTG printing is a popular choice for fashion designers looking to create unique and eye-catching designs on t-shirts and other apparel, with the ability to reproduce detailed artwork and graphics with precision.

- Branding and Promotion: DTG printing is ideal for branding and promotional purposes, allowing businesses and organizations to create custom-printed shirts and apparel with their logos, slogans, and messaging.

Conclusion

DTG printing has revolutionized the way t-shirts and other garments are customized and decorated, offering unparalleled flexibility, quality, and creativity. By understanding the process of DTG printing and its advantages, individuals, businesses, and organizations can create custom-printed garments that stand out and make a lasting impression. Whether it’s for personal expression, branding, promotion, or fashion design, DTG printing offers endless possibilities for creativity and customization, ensuring that every printed garment is a unique work of wearable art.