Germany Automotive Carbon Fiber Composites Market Overview

In the recent report published by Expert Market Research (EMR), the Germany automotive carbon fiber composites market size is under the spotlight, showcasing a significant surge in its valuation. As of 2023, the market has garnered remarkable attention, primarily due to the automotive industry’s shift towards lightweight and high-strength materials to enhance fuel efficiency and reduce carbon emissions. Projected to grow at a compound annual growth rate (CAGR) of 10.2% from 2024 to 2032, the Germany automotive carbon fiber composites market is expected to reach new heights, underpinned by the country’s stringent environmental regulations and the automotive sector’s innovation-driven growth strategies.

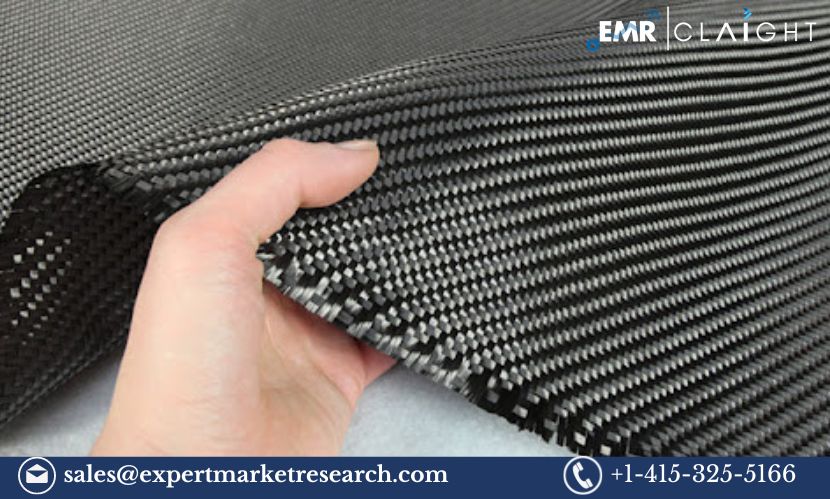

Carbon Fiber Composites:

Carbon fiber composites, known for their exceptional strength-to-weight ratio, have become a cornerstone in manufacturing high-performance and luxury vehicles. These materials offer unparalleled benefits, including significant weight reduction, enhanced fuel efficiency, and improved safety standards, making them a preferred choice among Germany’s leading automotive manufacturers.

The demand for carbon fiber composites is on an upward trajectory, fueled by the automotive industry’s relentless pursuit of sustainability and performance excellence. As vehicles become lighter without compromising on safety or durability, carbon fiber composites stand out as a revolutionary material, aligning with the global shift towards more environmentally friendly transportation solutions.

Read Full Report with Table of Contents@ https://www.expertmarketresearch.com/reports/germany-automotive-carbon-fiber-composites-market/requestsample

Key Drivers

Several factors contribute to the robust growth of the Germany automotive carbon fiber composites market.

- Weight Reduction and Performance: One of the primary drivers of the German automotive carbon fiber composites market is the need for weight reduction and improved performance. Carbon fiber composites are significantly lighter than traditional materials such as steel and aluminum, enabling automakers to achieve substantial weight savings without compromising structural integrity or safety. Lighter vehicles consume less fuel, emit fewer greenhouse gases, and offer better handling and acceleration, driving demand for carbon fiber composites in automotive applications.

- Technological Advancements: Advances in carbon fiber manufacturing processes, resin systems, and composite materials have expanded the capabilities and applications of carbon fiber composites in the automotive industry. Innovations such as automated layup, resin transfer molding (RTM), and out-of-autoclave (OOA) curing enable cost-effective production of complex-shaped components with high precision and consistency, opening up new possibilities for lightweight design and performance optimization.

- Environmental Regulations: Stringent environmental regulations and emissions standards in Germany and the European Union (EU) have prompted automakers to explore sustainable materials and manufacturing processes. Carbon fiber composites offer environmental benefits such as reduced fuel consumption, lower emissions, and improved recyclability compared to traditional materials. As regulatory pressure intensifies, automakers are increasingly integrating carbon fiber composites into their vehicle fleets to meet regulatory requirements and enhance environmental performance.

Germany automotive carbon fiber composites market Trends

- Electrification and Lightweighting: The electrification of vehicles and the transition towards EVs are driving demand for lightweight materials such as carbon fiber composites. EV manufacturers prioritize energy efficiency and range optimization, making lightweighting a key strategy for battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). Carbon fiber composites enable automakers to reduce vehicle weight, extend driving range, and enhance overall performance, positioning them as a preferred choice for next-generation electric mobility solutions.

- Integration of Carbon Fiber in Vehicle Architecture: Automakers are increasingly incorporating carbon fiber composites into vehicle architectures to achieve holistic weight reduction and performance improvements. By using carbon fiber for structural components such as chassis, body panels, and suspension systems, manufacturers can achieve significant weight savings while enhancing stiffness, crashworthiness, and durability. The integration of carbon fiber composites into mainstream vehicle platforms is accelerating, driven by advancements in materials, manufacturing processes, and design optimization.

- Collaboration and Partnerships: Collaboration and partnerships between automotive OEMs, carbon fiber suppliers, material manufacturers, and research institutions are driving innovation and market growth in Germany’s automotive carbon fiber composites sector. Joint ventures, technology alliances, and research consortia enable stakeholders to share expertise, resources, and best practices, accelerating the development and commercialization of carbon fiber-based solutions for automotive applications.

Read Full Report with Table of Contents@ https://www.expertmarketresearch.com/reports/germany-automotive-carbon-fiber-composites-market

Germany Automotive Carbon Fiber Composites Market Segmentation

The market can be divided based on Production Type and Application.

Breakup by Production Type

- Hand Layup

- Resin Transfer Moulding

- Vacuum Infusion Processing

- Injection Moulding

- Compression Moulding

Breakup by Application

- Structural Assembly

- Powertrain Component

- Interior

- Exterior

- Others

Competitive Landscape

Some of the major players explored in the report by Expert Market Research are as follows:

- BASF SE

- SGL Carbon SE

- Solvay Group

- Toray Industries, Inc.

- BMW AG

- Hexcel Corporation

- Teijin Limited

- Voith GmbH & Co. KGaA

- Muhr und Bender KG

- Cotesa GmbH

- Others

Challenges and Opportunities

Despite the promising growth prospects, the Germany automotive carbon fiber composites market faces certain challenges:

- Cost Considerations: The high cost of carbon fiber raw materials, manufacturing processes, and tooling remains a barrier to widespread adoption in mass-produced vehicles. Achieving cost parity with traditional materials such as steel and aluminum is essential to unlocking the full potential of carbon fiber composites in the automotive industry. Continuous research and development efforts focused on cost reduction, process optimization, and scale-up are critical to overcoming this challenge.

- Supply Chain Constraints: The availability and consistency of high-quality carbon fiber raw materials, resins, and intermediates are essential for the reliable production of automotive-grade composites. Supply chain disruptions, material shortages, and price volatility can impact production schedules, product quality, and market competitiveness. Strengthening partnerships with reliable suppliers, diversifying sourcing strategies, and investing in vertical integration can mitigate supply chain risks and ensure continuity of supply.

- Design and Manufacturing Complexity: Designing and manufacturing automotive components with carbon fiber composites require specialized expertise, equipment, and processes. Designing for manufacturability, optimizing layup configurations, and achieving consistent quality and performance across production batches pose challenges for automotive manufacturers. Investing in workforce training, advanced simulation tools, and automated manufacturing technologies can streamline production processes, reduce lead times, and improve cost efficiency.

Future Outlook

Looking ahead, the Germany automotive carbon fiber composites market is poised for continued growth and innovation. Key trends shaping the future of the market include:

- Materials Innovation: Advances in carbon fiber materials, resin systems, and composite technologies will drive the development of lightweight, durable, and cost-effective solutions for automotive applications. Tailored material formulations, multifunctional additives, and sustainable manufacturing processes will enhance the performance, affordability, and environmental sustainability of carbon fiber composites, expanding their adoption in mainstream vehicle platforms.

- Digitalization and Industry 4.0 Integration: The integration of digitalization, automation, and Industry 4.0 technologies will revolutionize the design, manufacturing, and assembly of automotive carbon fiber composites. Digital twin simulations, additive manufacturing, robotics, and artificial intelligence (AI) will enable virtual prototyping, predictive modeling, and adaptive manufacturing processes, accelerating innovation cycles and reducing time-to-market for new composite solutions.

- Circular Economy Initiatives: The transition towards a circular economy model will drive demand for sustainable materials and closed-loop recycling solutions in the automotive industry. Carbon fiber recycling technologies, such as pyrolysis, solvent-based processes, and mechanical reclamation, will enable the recovery and reuse of carbon fiber waste streams, reducing environmental impact and conserving valuable resources. Collaboration between stakeholders across the value chain will be essential to scale up recycling infrastructure and establish a circular carbon fiber economy.

Media Contact:

Company Name: Claight Corporation

Contact Person: George buttler, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com